Manufactured by co-extrusion polyolefin and polyamide, it has excellent tensile strength,

puncture resistance and waterproof properties. Specially designed for environment sealing

and protection of crimp splices and terminations.

Features

Shrink ratio: 3:1

Excellent puncture resistance

High peel strength.

Abrasion and corrosion resistance.

Waterproof and moisture resistance.

Various

Operating temperature: - 55°C to +125°C

Minimum shrink temperature: 80°C

Minimum fully recovery temperature: 130°C

Standard color: Red, blue, yellow

Technical Data

Dimensions

Property

Test Method

Values

Tensile strength

Room temp

≥16 MPa

Elongation at break

≥200%

Voltage withstand and breakdown Voltage

Withstand 2.5KV for 1minute and breakdown

Tensile strength at aging

158℃/7days

≥11.5 MPa

Elongation at break at aging

≥100%

Voltage withstand and breakdown Voltage at aging

At least half of un-aged breakdown voltage

Copper corrosion

No sign of degradation

Copper stability

No drop, no flow

Cold bend

-30℃/4 hrs

No cracking

Maximum secant modulus (2%)

250MPa

Volume resistivity

Min.1014 Ω·cm

Heat shock

250°C/4 hrs

No cracking

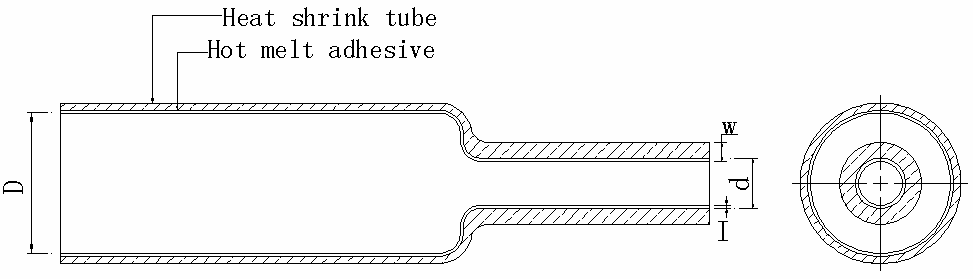

As Supplied (mm)

After Recovery (mm)

Standard length

m/roll

Φ3.2±0.3

0.35±0.05

Φ1.0

1.0±0.1

100

Φ4.8±0.3

0.45±0.05

Φ1.4

1.1±0.1

100

Φ7.0±0.3

0.45±0.05

Φ2.5

1.2±0.1

100

Φ6.8±0.3

0.5±0.05

Φ3.0

1.4±0.1

100

Φ7.0±0.3

0.5±0.05

Φ2.5

1.5±0.1

100

Φ8.3±0.3

0.65±0.05

Φ3.0

1.65±0.1

100