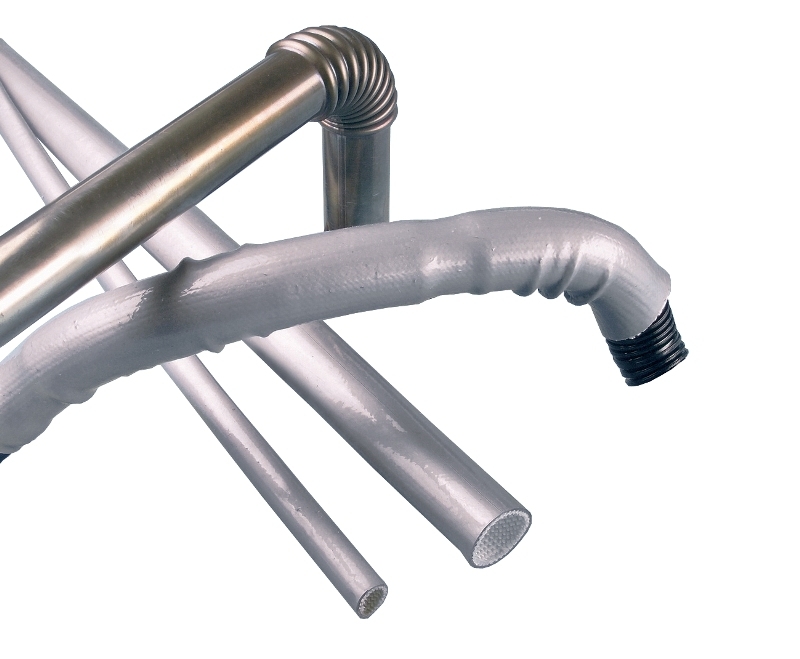

Designed for applications to seal and protect electrical and communication connections.Provides excellent mechanical protection to cable joints and terminations, flexible gaspipes, etc....

Features

High resistance to impact, abrasion, corrosion, UV and chemical. Rated for 1 kV, 90 °C continuous use. DH-WA is recommended for applications on light cables and wire harnesses which require waterproofing, protection of connector components, and thus encapsulates and seal components contained within the tubing.

Various

Operating temperature: -55°C to +110°C

Shrink temperature: 120°C

Resistant to UV-radiation.

Standard colors: Black. Special color: Red.

Packaging:Length as standards.

Technical Data

Property

Test Method

Typical Data

Tensile strength

ASTM D 2671

≥14MPa

Tensile strength after aging(158°C/168 hrs.)

ASTM D 2671

≥12 MPa

Elongation at break

ASTM D 2671

≥400%

Elongation at break after aging(158°C/168 hrs.)

ASTM D 2671

≥300%

Longitudinal shrinkage

UL224

0 to -10%

Density

ASTM D 792

1.05g/cm3

Dielectric strength

IEC 243

≥20 kV/mm

Volume resistance

IEC 93

≥1014Ω.cm

Eccentricity

ASTM D 2671

<30%

Copper stability

ASTM D 2671

Pass

Resistance to stress cracking

ASTM D 1693(50°C)

No Cracking

Water absorption

ISO 62(23°C/14 days)

<0.15%

Thermoplastic adhesive for DH-WA

Water absorption

ISO 62

<0.2%

Softening point

ASTM D E28

85℃

Peel strength (PE)

DIN 30672

4N/cm

Copper stability

ASTM D 2671

Non-corrosive

Resistance to fungus and decay

ISO 846

Pass

| Size | As Supplied(mm) | After Recovery (mm) |

Standard length

m

|

|

|

D-HW/DH-WA

(D)

|

Inside Diameter

Min. (D)

|

Inside Diameter

Max. (d)

|

Wall Thickness

Nominal. (t)

|

|

| 9/3 | 9 | 3 | 2.0 | 1.22 |

| 12/4 | 12 | 4 | 2.4 | 1.22 |

| 16/5 | 16 | 5 | 2.7 | 1.22 |

| 19/6 | 19 | 6 | 3.2 | 1.22 |

| 22/6 | 22 | 6 | 3.2 | 1.22 |

| 25/8 | 25 | 8 | 3.2 | 1.22 |

| 33/8 | 33 | 8 | 3.2 | 1.22 |

| 40/12 | 40 | 12 | 4.0 | 1.22 |

| 45/13 | 45 | 13 | 4.0 | 1.22 |

| 55/16 | 55 | 16 | 4.0 | 1.22 |

| 65/19 | 65 | 19 | 4.0 | 1.22 |

| 75/22 | 75 | 22 | 4.0 | 1.22 |

| 85/25 | 85 | 25 | 4.3 | 1.22 |

| 95/25 | 95 | 25 | 4.3 | 1.22 |

| 100/30 | 100 | 30 | 4.3 | 1.22 |

| 115/34 | 115 | 34 | 4.3 | 1.22 |

| 130/36 | 130 | 36 | 4.3 | 1.22 |

| 140/42 | 140 | 42 | 4.3 | 1.22 |

| 160/50 | 160 | 50 | 4.3 | 1.22 |

| 175/58 | 175 | 58 | 4.3 | 1.22 |

| 200/65 | 200 | 65 | 4.3 | 1.22 |