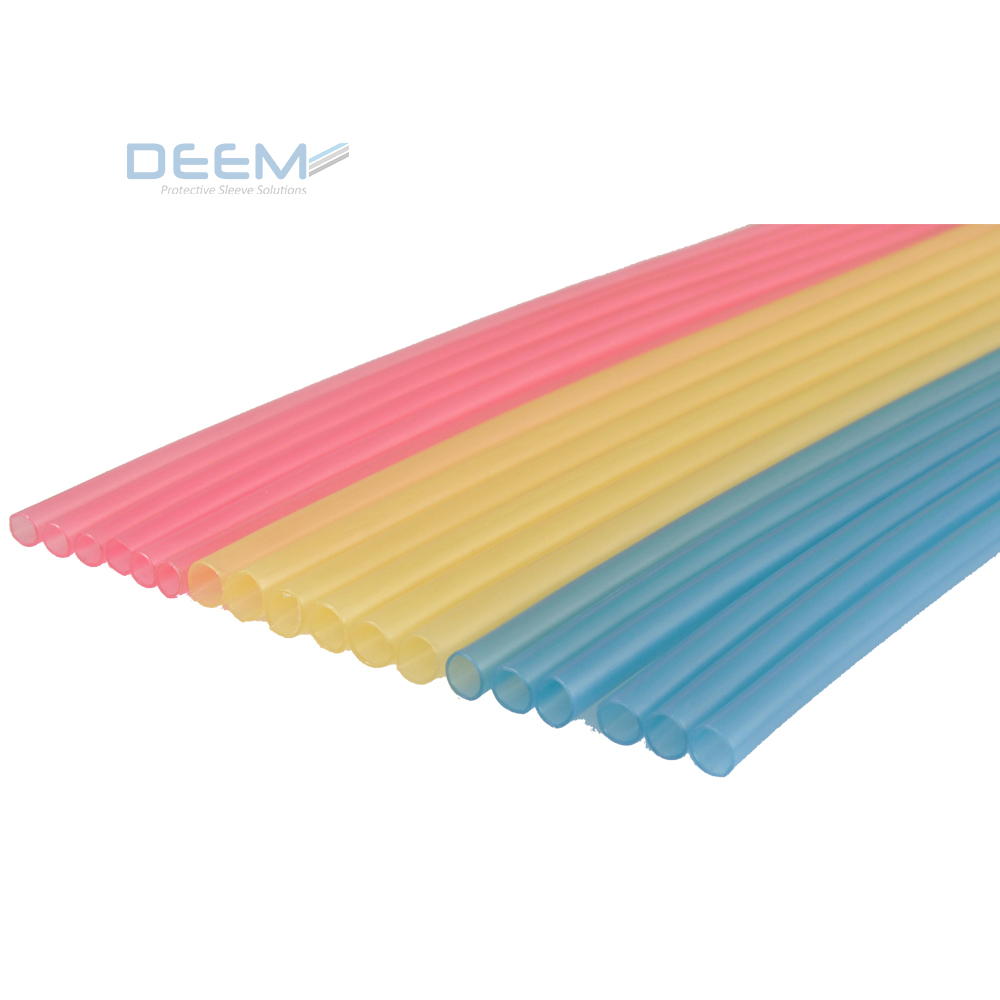

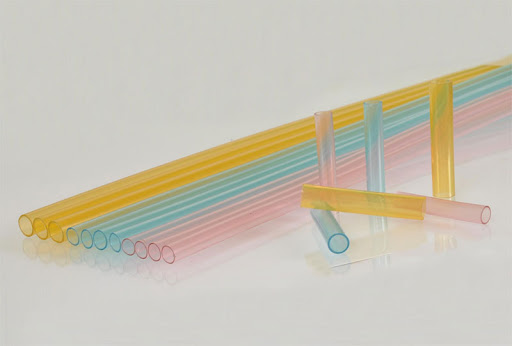

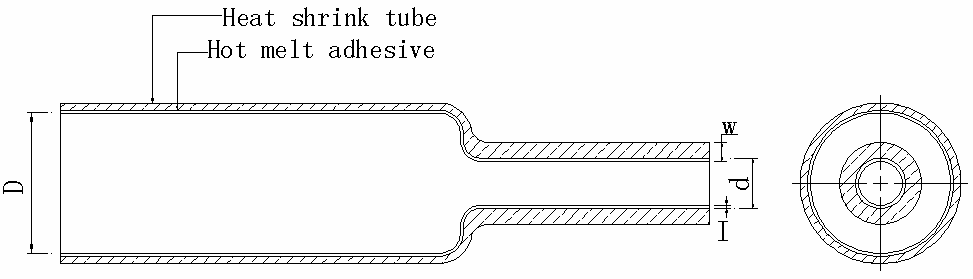

High transparency heat shrinkable tube, manufactured by coextrusion polyolefin and

polyamide, it has excellent tensile strength, puncture resistance and waterproof properties.

Especially designed for environmental sealing and protection of crimp splices and

terminations.

Features

Shrink ratio: 3:1

Abrasion and corrosion resistance

Water proof and moisture resistance

Highly translucence and elasticity.

Various

Operating temperature : -45°C~105°C

Minimum fully recovery temperature: 100°C

Standard color: Red, Blue, Yellow

Technical Data

Dimensions

Property

Test Method

Values

Tensile strength

Room temp

≥16 MPa

Elongation at break

≥200%

Voltage withstand and breakdown Voltage

Withstand 2.5KV for 1minute and breakdown

Tensile strength at aging

150°C/7days

≥11.5 MPa

Elongation at break at aging

≥100%

Voltage withstand and breakdown Voltage at aging

At least half of un-aged breakdown voltage

Copper corrosion

No sign of degradation

Copper stability

No drop, no flow

Cold bend

-40°C/4 hrs

No cracking

Maximum secant modulus (2%)

250MPa

Volume resistivity

Min.1014 Ω·cm

Heat shock

200°C/4 hrs

No cracking

As Supplied (mm)

After Recovery (mm)

Standard length

m/roll

Φ4.8±0.3

0.50±0.05

Φ1.4

1.2±0.1

100

Φ5.8±0.3

0.50±0.05

Φ1.7

1.3±0.1

100

Φ6.8±0.3

0.70±0.05

Φ2.1

1.5±0.1

100

Φ7.0±0.3

0.50±0.05

Φ2.5

1.5±0.1

100

Φ8.3±0.3

0.65±0.05

Φ3.0

1.65±0.1

100