Applications

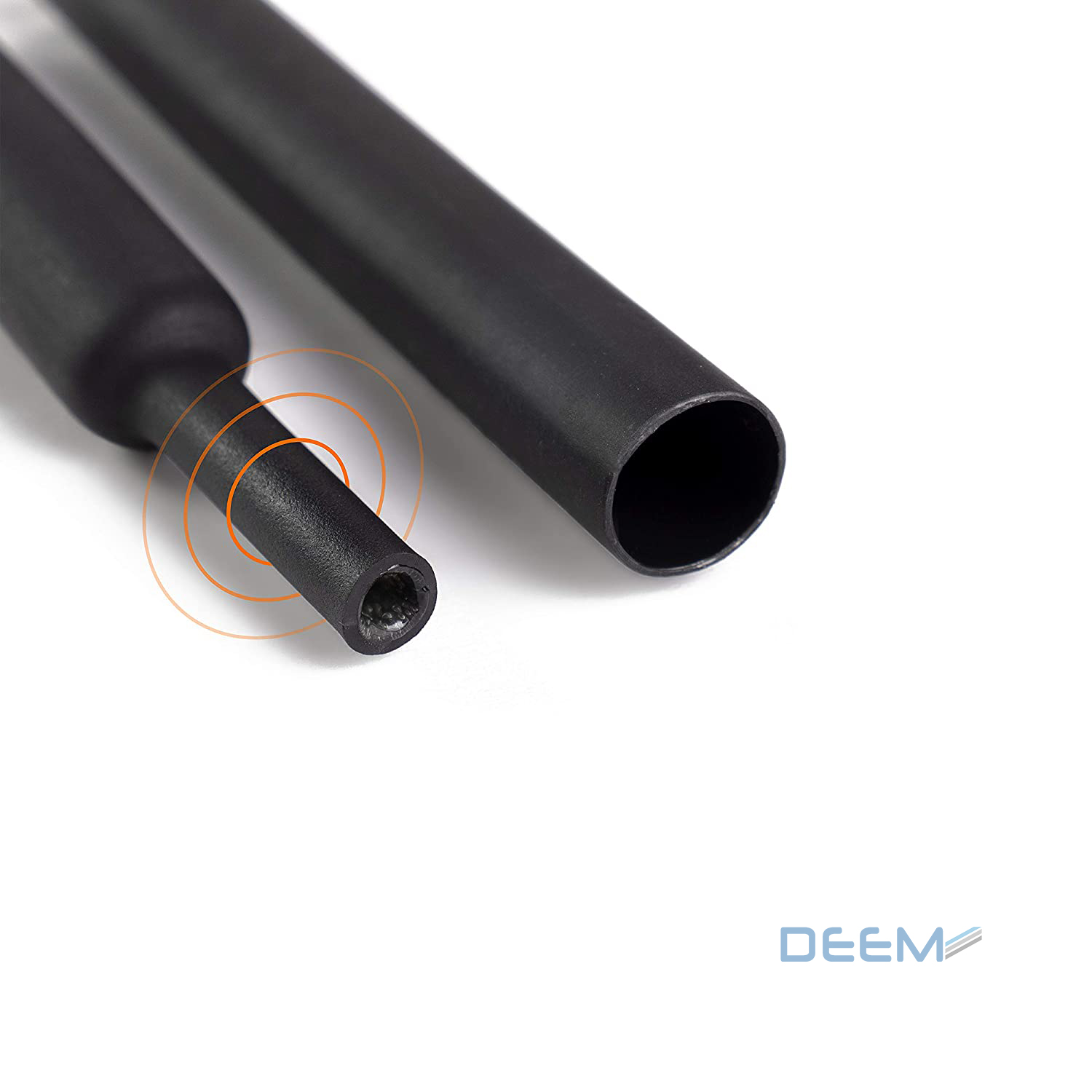

Designed to insulate and seal automotive wire connectors and components in the

automotive environment under the hood. After a special formula, it can work in a wide

temperature range.

Various

Material: Cross-linked polyolefin outer jacket, Hotmelt adhesive inner layer

Operating temperature:-40°C to +150°C

Minimum shrink temp. :110°C

Minimum full recovery temp.:135°C

Color: Black

Shrink ratio: 4:1 & 3:1

Insulation, Waterproof, Sealing

Meets: RoHS, ELV

Technical Data

| Property | Requirement | Method of test | |

| Material | Dimensions |

In accordance with Table

DIMENSIONS

|

ASTM D 2671 |

| Longitudinal change | -10% to+0% | ASTM D 2671 | |

| Tensile strength | 10.3Mpa minimum | ASTM D 2671 | |

| Ultimate elongation | 250% minimum | ASTM D 2671 | |

| Secant modulus 2%(recovered) | 150Mpa minimum | ASTM D 2671 | |

| Heat shock(250C/4hrs) |

No cracking,dripping or

flowing of outer jacket

|

ASTM D 2671 | |

| Dielectric strength(outer jacket only)* | 19.7kv/mm minimun | ASTM D 149 | |

| Volume resistivity | 1×1013Ω·cm minimun | ASTM D 257 | |

|

Splice

performance

|

Current leakage | 0.25μA maximum | |

| Thermal shock Current leakage | 0.25μA maximum | -40℃ to 135℃ for 25 cycles | |

| Heat aging Current leakage | 0.25uA maximum | 1000 hrs.at 150℃ | |

|

Fluid immersion

Current leakage

|

0.25μA maximum |

24 hrs.at 25℃±3℃

ASTM Reference Fuel C

VV-F-800 Diesel Fuel

24hr.at 100℃±3℃

ASTM #3 Oil

|

|

| Remove adhesive manually prior to testing | |||

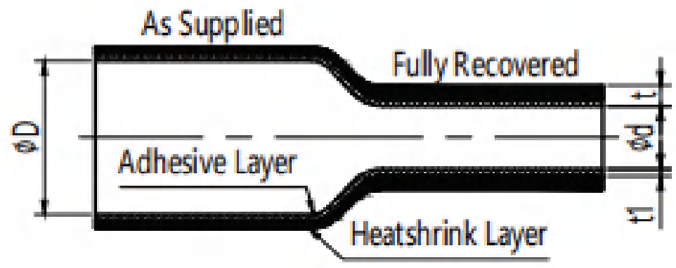

Dimensions

| As supplied | Fully recovered | ||

|

ID min

D

|

ID max

d

|

WT nom.

t

|

WT nom.

t1

|

| 5.10 | 1.30 | 1.2 | 0.7 |

| 7.62 | 1.65 | 1.5 | 0.8 |

| 9.02 | 2.29 | 1.6 | 0.8 |

| 11.56 | 2.54 | 2.3 | 1.4 |

| 14.10 | 3.00 | 2.3 | 1.4 |

| 17.78 | 4.45 | 2.5 | 1.5 |

| 27.94 | 8.38 | 2.5 | 1.5 |