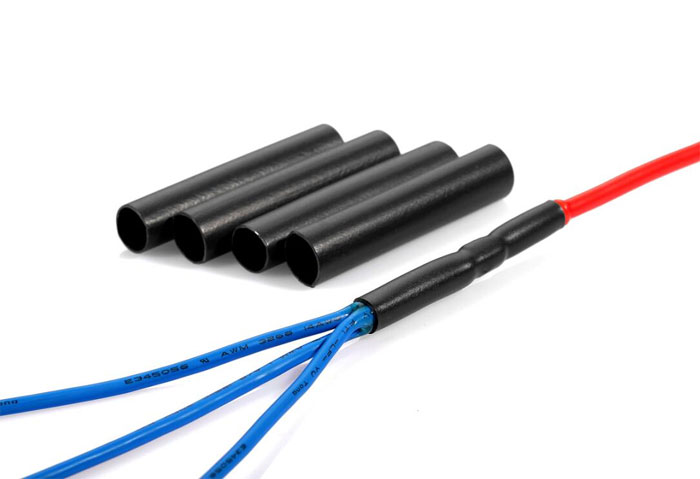

Specially design to insulate, seal and protect wire splices, terminations and component

in automotive industrial. High shrink ratio 4:1 and high temperature resistant and corrosion.

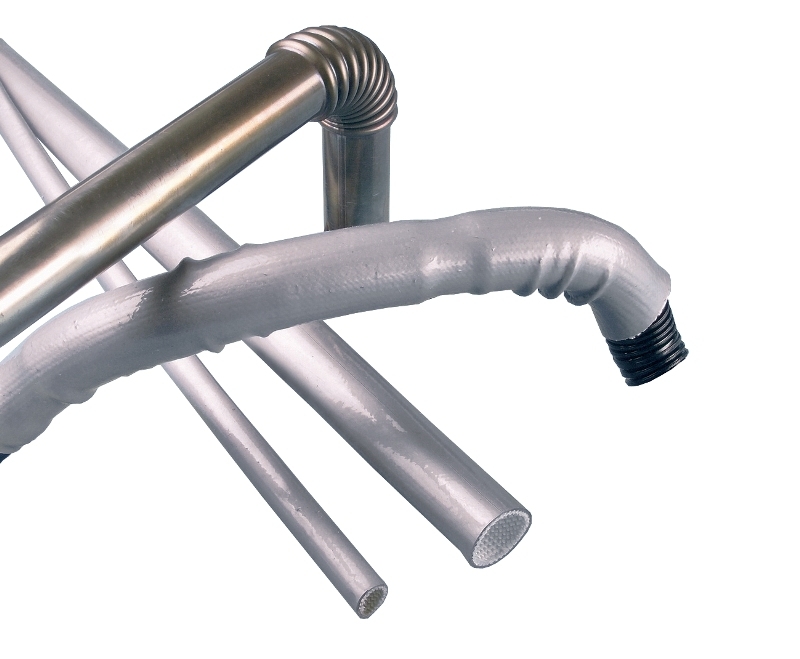

Semi-rigid outer wall provides excellent abrasion protection and strain relief for strict

environment requirement. Ideal for wire to metal splices and wire joints in automotive

industry. Clear tubing is specially designed for sealing and insulation of components where

see-through inspection is required.

Features

Flame retardant (Black only). High shrink ratio (4:1).

Semi rigid polyolefin outer layer. Polyamide adhesive liner.

Operating temperature: - 55°C to +130°C

Shrink temperature: 110°C

RoHS compliant

Various

Standard color: Black/clear

Standard packing on spools.or 1.22m sticks

Technical Data

Dimensions

Property

Test Method

Values

Black

Clear

Physical

Tensile strength

ASTM D2671

≥14 MPa

≥12 MPa

Elongation at break

ASTM D2671

2400%

Tensile strength at aging

ASTM D2671

≥14 MPa

≥12 MPa

Elongation at break at aging

ASTM D2671

≥350%

Outer layer density

ASTM D792

1.25

1.00

Water absorption

ASTM D570

≤0.5%

Heat shock(200°C/4hrs)

ASTM D2671

No drop, no flow

Low Temperature flexibility(-40°C/4hrs)

Min.1014 Ω·cm

No cracking

Ring-ball soft point (adhesive liner)

ASTM E28

120℃+5℃

Electrical

Volume resistivity

ASTM D2671

≥1014 Ω·cm

Dielectric strength

ASTM D2671

≥16/KV/mm

Chemical

Flammability

ASTM D2671

Self-extinguish in 30s

Size

As Supplied (mm)

After Recovery (mm)

Standard length

mm. (D)

m/spool

4

4.0

φ2.5

1.2

200

6

5.7

φ3.0

1.3

100

8

7.4

1.7

1.5

100

12

10.8

2.5

2.0

50

18

17.8

4.4

2.3

50