Heat Shrinkable splices provide a permanent environmental seal.

The polymer used in the production of the heat shrink tube is specially adapted to be crimped. Ideal for electrical equipment repairs, maintenance and outdoor electrical cabling.

Features

Operating temperature: -55°C to +125°C

Minimum shrink temperature: 110°C

No wire damage thanks to a lower shrink temperature.

100% waterproof, excellent fluid resistance. Very high abrasion resistance.

Color: Red, Blue, Yellow

Shrink ratio: 3:1.

Technical Data

Property

Test Method

Typical Data

Tensile Strength

ASTM D 2671

28MPA(min)

Elongation at break

ASTM D 2671

500%(min)

Longitudinal Shrinkage

UL224

0 to-10%

Heat Shock

250°C/4hrs.

No cracking, Flowing of out wall

Heat resistance

165℃/168hrs.

No cracking, Flowing of out wall

Cold bend(-40C/1hr.)

ASTM D 2671

No cracking

Voltage withstand (AC 2500V,60 sec.)

ASTM D 2671

No Breakdown

Volume Resistivity

ASTM D 876

1014Ω.cm

Copper corrosion

UL 224

Pass

Water absorption

ASTM D570

≤0.5%

Fluid resistance (23°C/24 hrs)

ASTM D 2671

Good to excellent

Specific Gravity

ASTM D 792

1.01g/cm3

| DC-SC | Wire range | AWG | As supplied (mm) | After recovery (mm) | |

| Inside diameter | Inside diameter | Cut length(mm) | |||

| Light Yellow Clear | 0.1-0.5mm2 | 26-24 | 3.0 | 1.0 | 26 |

| Red | 0.5-1.5mm2 | 22-18 | 4.5 | 1.5 | 38 |

| Blue | 1.5-2.5mm2 | 16-14 | 5.5 | 1.8 | 38 |

| Yellow | 4-6mm2 | 12-10 | 6.5 | 2.2 | 42 |

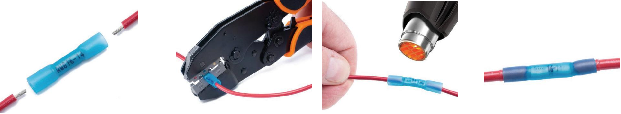

Installation instructions

1- Select butt splice to suit conductor size.2- Strip insulation to 8mm and insert into the splice barrel.

3- Crimp using the correct tool for pre-insulated splices (tool recommended : DM-CRIMP SEAL TOOL)

4- Apply heat to the crimp seal with hot air gun until tubing recovers and the adhesive flows from the end of the splice.