Introduction

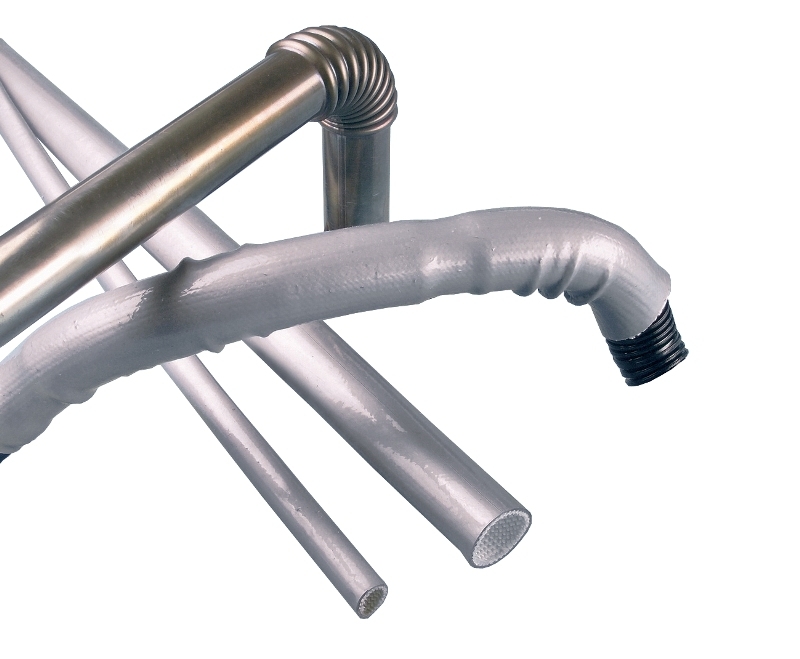

ApplicationsIdeal for the strain relief and mechanical protection of the brake or fuel line,

hydraulic line which is subject to bending for clamping operations during manufacturing,

installation or operation.

Features

Semi rigid polyolefin outer layer.

Thermal melt adhesive liner.

Low shrink temperature.

Halogen free.

Operating temperature: - 40°C to +80°C

Shrink temperature: 110°C

Shrink ratio: 1.5:1

RoHS compliant

Various

Standard color: Black

Standard packing on spools.

Technical Data

| Property | Test Method | Values | |

| Physical | Tensile strength | ASTM D2671 | ≥12 MPa |

| Elongation at break | ASTM D2671 | ≥350% | |

| Tensile strength at aging | ASTM D2671 | ≥12 MPa | |

| Elongation at break at aging | ASTM D2671 | ≥300% | |

| Outer layer density | ASTM D792 | 1.0 | |

| Water absorption | ASTM D570 | ≤0.4% | |

| Heat shock (200°C/4hrs) | ASTM D2671 | No drop, no flow | |

| Low Temperature flexibility(-40°C/4hrs) | ASTM D2671 | No cracking | |

| Horizontal impact resistance(-35°C) | Min.1014 Ω·cm | No damage | |

| Drop impact resistance(-35°C) | ASTM D746 | No damage | |

| Stress cracking resistance(-35°C) | ASTM D1693 part5.3.6 | ||

| Electrical | Volume resistivity | ASTM D2671 | ≥1014 Ω·cm |

| Dielectric strength | ASTM D2671 | ≥15/KV/mm | |

| As Supplied(mm) | After Recovery (mm) | Standard length | ||

|

Inside Diameter

Min.(D)

|

Inside Diameter Max. (d) | Total Wall Thickness Nor. (t) | Adhesive Thickness | m/spool |

| 5.5 | 3.3 | 1.0 | 0.2 | 200 |

| 6.5 | 4.7 | 1.0 | 0.2 | 200 |

| 8.5 | 6.0 | 1.0 | 0.2 | 100 |

| 11 | 7.0 | 1.0 | 0.2 | 100 |

| 15 | 9.5 | 1.0 | 0.2 | 100 |

More Products