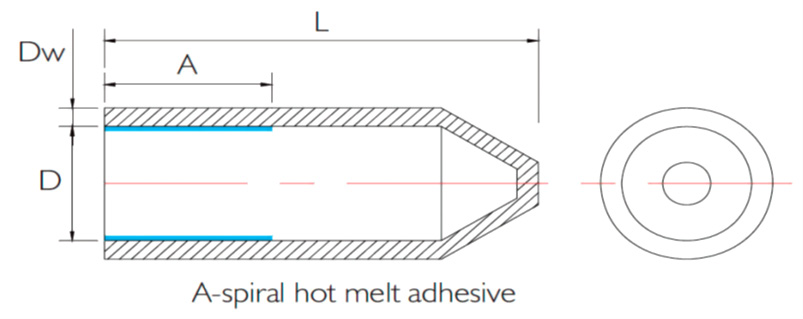

Recommended for use both in open air and on underground power distribution cables with PVC, lead or XLPE sheets. Definitive recovery with the layer of spiral coated hot melt adhesive.

Features

Resistant to oxidation, ozone, UV radiation. Protects power cables up to 1000 V and telecommunication cables. Very easy to fit over cable end. Environment definitive watertight seal.

Material: thermally stabilized cross linked polyolefin, coated with special hot melt adhesive.

VariousOperating temperature: -55°C to +110°C

Minimum full recovery: 120 °C

Effectively offering protection against oxidation, ozone,

UV-radiation.

Coated with hot melt adhesive to ensure environment seal.

Standard color: Black.

Technical Data

Dimensions

Property

Test Method

Typical Data

Operating temperature

IEC 216

-55°C to+110℃

Tensile strength

ASTM D 638

>14 MPa

Elongation at break

ASTM D 638

>400%

Elongation at break after aging

150C/168 hrs.

>300%

Density

ASTM D 792

1.05

Flammability

/

Flammable

Dielectric strength

IEC 243

>15 kV/mm

Volume resistance

IEC 93

>1014Ω.cm

| Size | As Supplied (mm) | After Recovery(mm) | Cable Diameter (mm) | |||

| (D) | D(min) | D(max) | A(±10%) | L(±10%) | Dw(±5%) | |

| Standard length end caps | ||||||

| 12/4 | 12 | 4.0 | 15 | 40 | 2.6 | 4-10 |

| 14/5 | 14 | 5.0 | 18 | 45 | 2.6 | 5-12 |

| 20/6 | 20 | 6.0 | 25 | 55 | 2.8 | 6-16 |

| 25/8.5 | 25 | 8.5 | 30 | 68 | 2.8 | 10-20 |

| 35/16 | 35 | 16.0 | 35 | 83 | 3.3 | 17-30 |

| 40/15 | 40 | 15.0 | 40 | 83 | 3.3 | 18-32 |

| 55/26 | 55 | 26.0 | 50 | 103 | 3.5 | 28-48 |

| 75/36 | 75 | 36.0 | 55 | 120 | 4.0 | 45-68 |

| 100/52 | 100 | 52.0 | 70 | 140 | 4.0 | 55-90 |

| 120/60 | 120 | 60.0 | 70 | 150 | 4.0 | 65-110 |

| 145/60 | 145 | 60.0 | 70 | 150 | 4.0 | 70-130 |

| 160/82 | 160 | 82.0 | 70 | 150 | 4.0 | 90-150 |

| 200/90 | 200 | 90.0 | 70 | 160 | 4.2 | 100-180 |