Introduction

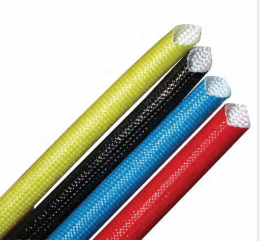

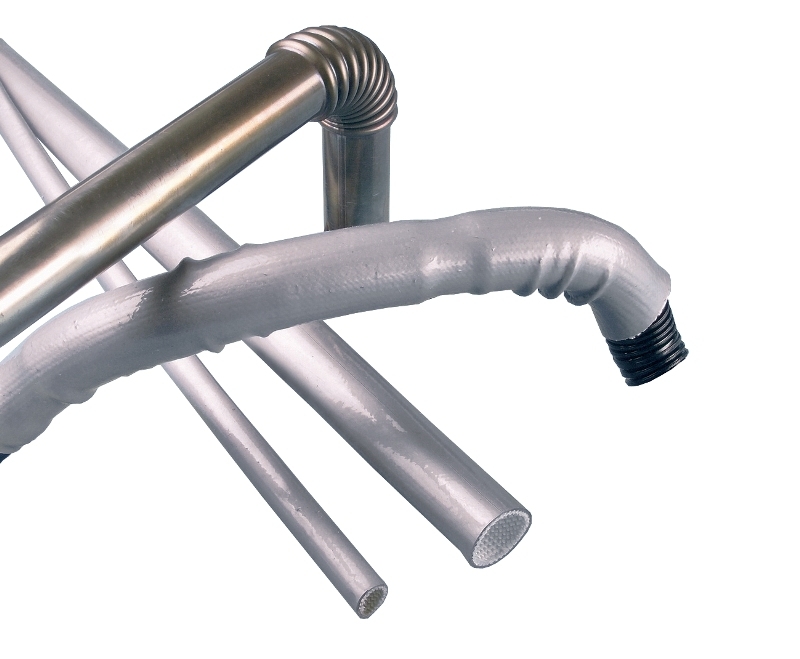

FeaturesGeneral-purpose polyvinyl chloride (PVC) sleeves are made of general purpose polyvinyl chloride (PVC) colloidal particles, dried, heated and melted by an extruder, compressed to form, cooled with cold water, and rolled up. Has good flexibility, mechanical properties, dielectric properties, flame retardancy, etc. Meet the

environmental standards. Widely used electrical appliances, motors, transformers lead wire insulation, wiring harnesses, insulating sleeve protection for electronic components, gas, liquid circulation pipes and so on.

Various

1 .Flame retardant, environmental protection

2.Operating temperature : -20?C to +105°C

3. Environ mental standards : RoHS

4.Standard Color:White,Black. Other colors available on request.

5.Material:PolyvingI Chloride

Technical Data

| Property | Test Method | Typical Data | |

| Shore Hardness | Hardness Tester | 60P(80A±2A) | |

| Voltage level | Withstand voltage tester | 600V | |

| Temperature Range | Heat Aging Oven | -30℃-105℃ | |

| Enduring voltage | Before aging | 23℃ | 2500V/60sec |

| After aging | 136 C168hr | 2500V/60sec | |

| Tensile strength | Before aging | 23C | ≥10.4 Mpa |

| After aging | 136 ℃168hr | ≥7.3 Mpa | |

| Heat Aging Elongation | Before aging | 23℃ | ≥100% |

| After aging | 136 C168hr | ≥100% | |

| Flexibility | 136 ℃168hr | No cracks | |

| Cold bend | -30CNo cracks the same hard | -30℃ 1hr | |

| Copper stability | 136℃168hr | No eroding | |

| Flame resistance | UL224 | VW-1 | |

| Size |

Inside Diameter

(mm)

|

Wall Thickness(mm) |

Standard length

m/spool

|

|

| Inch | 300V | 600V | ||

| 3/64 | 1.2±0.15 | 0.30±0.05 | 0.45±0.05 | 305 |

| 1/16 | 1.5±0.15 | 0.30±0.05 | 0.45±0.05 | 305 |

| 3/32 | 2.4±0.2 | 0.30±0.05 | 0.45±0.05 | 305 |

| 1/8 | 3.2±0.2 | 0.40±0.05 | 0.50±0.05 | 305 |

| 3/16 | 4.8±0.3 | 0.45±0.05 | 0.55±0.05 | 305 |

| 1/4 | 6.4±0.3 | 0.45±0.05 | 0.55±0.05 | 152 |

| 5/16 | 8.0±0.35 | 0.45±0.05 | 0.55±0.05 | 152 |

| 3/8 | 9.5±0.35 | 0.50±0.05 | 0.55±0.05 | 152 |

| 7/16 | 11.1±0.35 | 0.55±0.10 | 0.65±0.10 | 152 |

| 1/2 | 12.7±0.35 | 0.55±0.10 | 0.65±0.10 | 152 |

| 9/16 | 14.3±0.4 | 0.65±0.10 | 0.75±0.10 | 76 |

| 5/8 | 16.0±0.4 | 0.65±0.10 | 0.75±0.10 | 76 |

| 3/4 | 19.0±0.4 | 0.65±0.10 | 0.75±0.10 | 76 |

| 7/8 | 22.0±0.5 | 0.75±0.15 | 0.85±0.15 | 76 |

| 1 | 25.0±0.5 | 0.75±0.15 | 0.85±0.15 | 76 |

More Products