Heat Shrinkable tape with low melting point adhesive layer for wrap around repair. Usually applied by enwind around the electrified object with half of tape overlapping previous turn.

The tape, when heated, shrinks around the substrate while hot melt adhesive fill the gaps and fusion with the tape to form into one piece insulation.

Applications

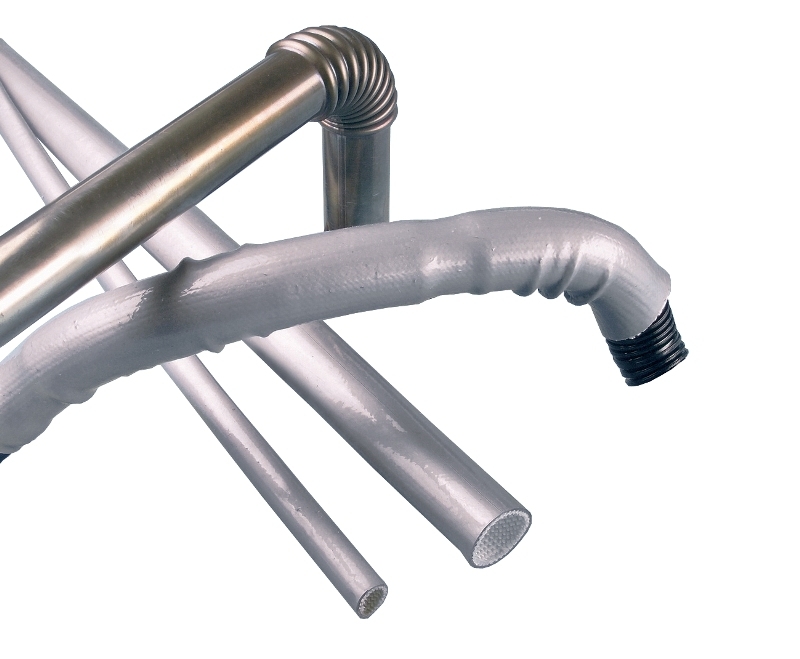

Emergency repair of electrical power system .insulation and protect of odd-shaped electrified objects, where tubal / sleeve shaped insulation materials are not applicable.

Reduce space allowance between phase to phase bus bar.

Features/Benefits

Low melting point high polymer adhesive layer for easy installation.

Conform to irregular shaped objects where tubal / sleeve jacket insulation material is not applicable.

Compatible with most other insulation materials.

Temperature Range

Operating Temperature : -40 °C ~ 105 °C

Shrink Temperature : 125 °C

Standard Color: Red, Yellow, Black, Green

Technical data

Property

Method of Test

Value

Flammability

GB1046

Oxygen Index ≥30

Water absorption

GB1034

≤0.1%

Low temperature flexibility (-40C for 4 hours)

pass

Corrosion (temperature 23±2℃, humidity 95% for 4 hours)

pass

Tensile strength

GB1040

≥14.0MPa

Ultimate elongation

GB1040

≥400%

Aging test (168C for 7days)

GB1040

80% of Before Aging

Break down strength

GB1408

27~30 kV/mm

Electric impact

GB311

75kV/±10times

current

GB2706-89

31.5kA

current

GB2706-89

80.0kA,peak

Volume Resistivity

GB1044

1014Ω.cm

Dielectric constant

GB1049

2.5--3.5

Dimensions

Model Number

Volt class/KV

Tape thickness

Tape width/mm

DM-T 1

6-15

0.8-1.0mm

25

5

DM-T2

6-15

0.8-1.0mm

50

5