Applications

Features

Abrasion resistance polyolefin material.

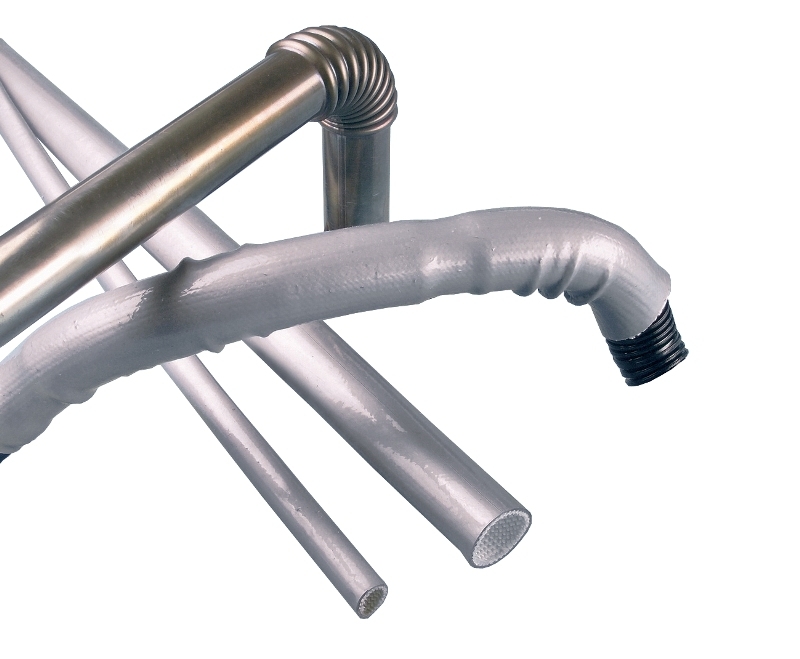

Heat shrink sleeve with inner air groove.

Smooth shrinkage, air-tight seal when bent.

Halogen free.

Various

Operating temperature : -55°C to +125°C

Minimum shrink temperature: 70°C

RoHs compliant

Shrink ratio: 2:1 (3:1 available.)

Technical Data

Property

Test Method

Typical Data

Operating temperature

UL 224

-55C to+125°℃

Tensile strength

ASTM D2671

>14 MPa

Elongation at break

ASTM D2671

≥450%

Tensile strength at aging

ASTM D2671

≥12Mpa

Elongation at break at aging

ASTM D2671

≥350%

Density

ASTM D792

1.1

Water absorption

ASTM D570

≤0.5%

Heat shock (200C/4hrs)

ASTM D2671

No drop, no flow

Low Temperature flexibility

ASTM D2671

-55°C/4hrs, no cracking

Hardness(Shore D)

ASTM D2671

30-40 HD

Dielectric strength

ASTM D2671

≥20 KV/mm

Volume resistance

ASTM D2671

≥1014Ω.cm

Dimensions/Shrink ratio 2:1

Size

As Supplied (mm)

After Recovery(mm)

Inch. (D)

20/9

20

9

0.9

100

25/12

25

12

0.9

50

30/15

30

15

1.0

50

35/17

35

17

1.1

50

40/20

40

20

1.2

50

50/25

50

25

1.2

25

60/28

60

28

1.2

25

Dimensions/Shrink ratio 3:1

*Spools as standards. 100 m. or 50 m. sticks, special spool lengths or cut pieces available on request.

Size

As Supplied (mm)

After Recovery (mm)

Inch. (D)

18/6

18

6

1.2

100

27/9

27

9

1.2

50

39/13

36

13

1.5

50

51/17

51

17

1.5

25

Special sizes (up to 7 inches) and other special features available on request